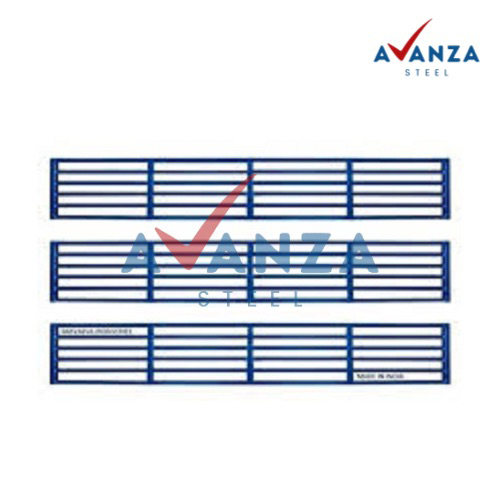

Vertical Cuplock

Product Details:

- Sleeve size 150 mm (Standard Spigot Sleeve)

- Color Blue, Silver, or as required

- Features High strength, Easy assembly/disassembly, Corrosion resistant

- Product Type Vertical Cuplock

- Material Steel

- Components Other

- Diameter 48.3 Millimeter (mm)

- Click to View more

X

Vertical Cuplock Price And Quantity

- 100 Kilograms

Vertical Cuplock Product Specifications

- 150 mm (Standard Spigot Sleeve)

- Other

- Blue, Silver, or as required

- Painted / Galvanized

- 48.3 Millimeter (mm)

- High strength, Easy assembly/disassembly, Corrosion resistant

- Vertical Cuplock

- 250 Kilograms (kg)

- Steel

- 48.3 mm x length

- 3.0 mm - 3.2 mm Millimeter (mm)

- Scaffolding support for construction, access, and staging

- 500 mm to 3000 Millimeter (mm)

Vertical Cuplock Trade Information

- 100 Kilograms Per Month

- 7 Days

Product Description

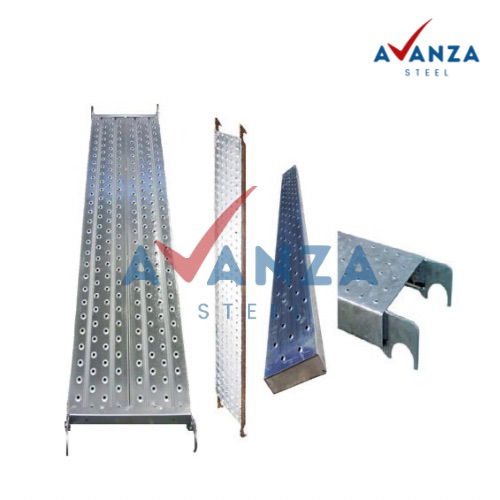

Cuplock scaffolding is a modular system made from high tensile steel with a hot-dip galvanized finish for corrosion resistance. It features node points that allow up to four horizontal members to be connected in one locking action. The system comprises standards, ledgers, and diagonal braces, designed for high load-bearing capacity. Its unique cup and blade mechanism eliminates the need for bolts or nuts, ensuring quick erection and dismantling. Cuplock systems are compatible with different work environments and height requirements

Uses in the Scaffolding Industry

- Used in high-rise construction for safe working platforms.

- Preferred for heavy-duty applications like bridges and flyovers.

- Offers easy adaptability for circular and curved structures.

- Widely used in industrial plants and maintenance projects.

- Ensures quick setup and reduced labor time.

Engineered for Strength and Compatibility

Our vertical cuplock standards combine high-strength forged mild steel and an integral spigot socket, allowing reliable assembly and enhanced compatibility with various scaffolding systems. The robust welded cups and spigot pin design make for secure and simple jointing, supporting up to 250 kg per platform. Each component is crafted to ensure outstanding durability, even during multiple reuse cycles.

Simple, Tool-Free Installation

These cuplock verticals are designed for manual installation, requiring no special toolsjust straightforward assembly. The plain or welded end caps and sliding upper cups facilitate rapid setup and disassembly, reducing project time and labor. Their innovative design ensures that assembly/disassembly is both intuitive and safe for workers at any site.

Adaptable Solutions for Construction Needs

Available in various lengths (500 mm3000 mm) and finished in blue, silver, or custom colors, these verticals suit diverse scaffolding, staging, and access requirements. Supplied in bundles as per requirement, their mild steel construction and protective surface treatments maximize usage life and corrosion resistance, making them a dependable choice for exporters, manufacturers, and suppliers.

FAQs of Vertical Cuplock:

Q: How do I assemble the vertical cuplock with integral spigot and socket?

A: Assembly is straightforward and manualsimply align the spigot of one standard with the socket of the next, and secure the cups at designated positions. No special tools are required, ensuring efficient and quick installation on site.Q: What are the main benefits of using this vertical cuplock system?

A: This system provides high strength, easy installation and removal, excellent corrosion resistance due to painted or galvanized surfaces, and compatibility with other cuplock scaffolding. Its robust design allows for repeated use, enhancing safety and reducing replacement costs.Q: When should I use this type of vertical cuplock?

A: These vertical cuplocks are ideal for any construction, access, or staging project requiring reliable, modular scaffolding. Their flexibility and strength make them suitable for both temporary and long-term applications.Q: Where can vertical cuplock scaffolding be used?

A: Vertical cuplock systems can be deployed at building construction sites, industrial maintenance projects, event staging, and anywhere robust scaffolding support is essential.Q: What is the usage process and expected service life?

A: Installation involves manually stacking and locking the standards using the integral spigot and socket, with no need for extra tools. Designed for repeated cycles, they offer long service life, retaining strength and form over multiple applications.Q: How does this cuplock ensure compatibility with other systems?

A: The 48.3 mm diameter and standard spigot sleeve design align with other cuplock systems, allowing seamless integration and flexible expansion as your project demands.Q: What sizes and finishes are available for the vertical cuplock?

A: Available in lengths from 500 mm to 3000 mm, with thicknesses from 3.0 mm to 3.2 mm, and in finishes such as blue, silver, or as required, with surface treatment options including painting or galvanization for enhanced corrosion protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cuplock Scaffolding' category

"We are accepting only bulk order quantity."