Scaffolding System

Product Details:

- Color Blue / Silver / Customized

- Constitute Steel tubes, forged steel cups, welded assemblies

- Features High load capacity, Quick assembly and dismantling, Corrosion resistant, Heavy duty

- Technique Welded fabrication, Hot rolled

- Sleeve size 150 mm

- Weight 19 kg - 31 kg per standard

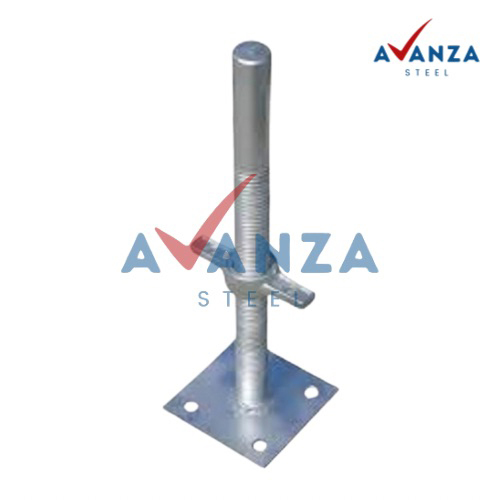

- Prop Head Fixed / Adjustable U-Head / Flat Head

- Click to View more

Scaffolding System Price And Quantity

- 62000 INR/Ton

- 100 Piece

Scaffolding System Product Specifications

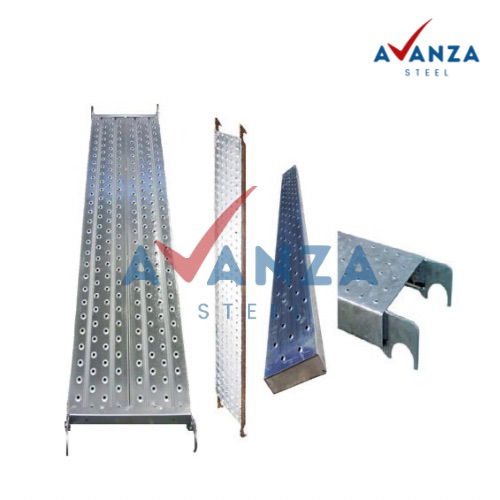

- Vertical Standards, Horizontal Ledgers, Base Plates, Planks, Diagonal Braces, Jack Base, Couplers, Guard Rails

- Standard sizes: 2.0m, 2.5m, 3.0m

- 150 mm

- 3.2 mm to 4 mm

- 48.3 mm

- Hot Dip Galvanized / Painted

- Cuplock System

- Integral locking pin system

- Up to 250 kg/m

- 1350 mm

- Fixed / Adjustable U-Head / Flat Head

- Welded fabrication, Hot rolled

- Construction, maintenance, staging, industrial access

- Steel tubes, forged steel cups, welded assemblies

- 19 kg - 31 kg per standard

- 1000 mm to 3000 mm

- Customizable, up to 10 meters or as required

- High load capacity, Quick assembly and dismantling, Corrosion resistant, Heavy duty

- Q235 or Q345 Grade Steel

- Blue / Silver / Customized

Scaffolding System Trade Information

- 500 Piece Per Day

- 7 Days

- All India

Product Description

Scaffolding System is a temporary structure used in construction, maintenance, and other industries to provide safe and stable access to elevated areas, support materials, and enable workers to perform tasks at the height. This can be adjusted, expanded, or reconfigured to suit the specific requirements of a project, making them highly versatile in different environments. They are widely used for exterior work on buildings, such as window cleaning, painting, or facade repair. With a wide range of types and designs to choose from, Scaffolding System can be tailored to meet the specific needs of a project.

A scaffolding system is a temporary structure comprising standards, ledgers, transoms, and platforms made of steel or aluminum. Designed to support workmen and materials during construction, repair, or maintenance. Systems can be modular (like Cuplock or Ringlock) or tube and coupler-based, offering versatility in complex geometry. Load capacity depends on configuration and material grade, typically supporting 200 - 750 kg/m2.

Uses in the Scaffolding Industry

- Enables safe access to high or hard-to-reach areas.

- Used for supporting workers, tools, and materials.

- Adaptable for facade work, painting, and insulation.

- Essential for industrial, residential, and commercial projects.

- Customizable based on project height and span.

High Standards of Safety and Strength

Engineered to meet EN 12810, EN 12811, and IS 2750 standards, this scaffolding system ensures high reliability for construction and industrial applications. Each component is fabricated with precision-welded Q235 or Q345 grade steel, offering enhanced structural integrity, safety, and capable of withstanding demanding site conditions.

Versatile Design and Easy Customization

Designed for quick assembly and dismantling, the system uses pin-integral locking and a cup and blade connection for hassle-free setup. With adjustable jack bases and customizable heights up to 10 meters and erection up to 30 meters (when designed properly), the components accommodate a variety of project needs in India and abroad.

Corrosion Resistance for Longevity

All structural elements are finished with hot-dip galvanization or painting, offering a zinc thickness of 60-100 m. This ensures the scaffolding remains corrosion-resistant, extending its service life in both indoor and outdoor environments, and minimizing maintenance requirements on site.

FAQ's of Scaffolding System:

Q: How does the cup and blade connection system facilitate scaffolding assembly?

A: The cup and blade connection system uses integral locking pins, allowing vertical and horizontal components to interlock securely every 500 mm. This design greatly accelerates setup and dismantling, ensuring safety and reducing labor time on construction sites.Q: What standards does this scaffolding system comply with?

A: This system is engineered in accordance with EN 12810, EN 12811, and IS 2750 standards, ensuring it meets stringent safety and performance benchmarks required for construction and maintenance applications.Q: When should I use this scaffolding system during a construction project?

A: This scaffolding system is best utilized during phases requiring elevated access, secure platforms, or heavy-duty load support, such as structural assembly, facade works, or industrial maintenance, with platform loading up to 250 kg/m2.Q: Where can the scaffolding system be deployed?

A: Ideal for use at construction sites, maintenance projects, industrial facilities, and staging setups, the system can be deployed indoors or outdoors, thanks to its robust build and corrosion-resistant zinc coating.Q: What is the process for adjusting the height of the scaffold?

A: Height can be easily modified using the adjustable jack base, which offers up to 500 mm of fine adjustment. Additionally, the modular design allows erection up to 30 meters with proper engineering, and customization of vertical standards to suit project demands.Q: What are the main benefits of using this scaffolding system?

A: Key benefits include high load capacity, quick assembly and dismantling, excellent corrosion resistance, compatibility with heavy-duty tasks, and adaptability in sizing, making it suitable for diverse construction and industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+