SHEET PILES

57000.0 INR/Metric Ton

Product Details:

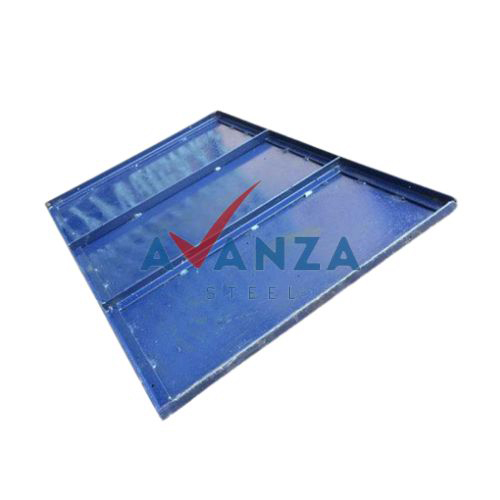

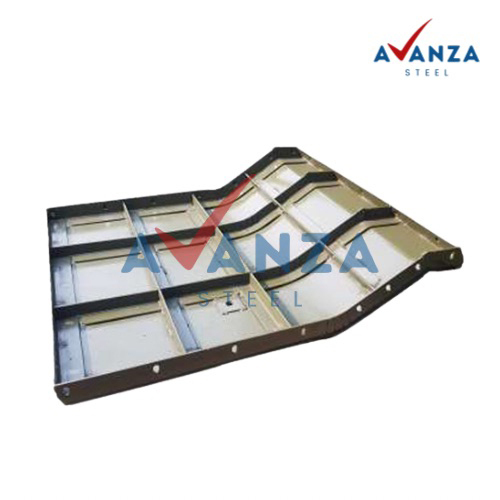

- Product Type Sheet Piles

- Material High quality structural steel

- Usage Retaining walls, waterfront structures, excavation support

- Application Marine construction, bridge abutments, flood protection, basement construction

- Size Customized as per project requirement, Commonly available in 400 mm to 800 mm width and lengths up to 18 m

- Weight Ranges from 40 kg/m to 75 kg/m depending on section and dimensions

- Color Metallic Grey

- Click to View more

X

SHEET PILES Price And Quantity

- 57000.0 INR/Metric Ton

- 100 Ton

SHEET PILES Product Specifications

- High strength, interlocking design, corrosion resistance, efficient earth retention

- Sheet Piles

- Customized as per project requirement, Commonly available in 400 mm to 800 mm width and lengths up to 18 m

- Marine construction, bridge abutments, flood protection, basement construction

- Designed for heavy load bearing and earth retention applications

- Typically 400 - 620 MPa

- Metallic Grey

- High quality structural steel

- Ranges from 40 kg/m to 75 kg/m depending on section and dimensions

- Retaining walls, waterfront structures, excavation support

SHEET PILES Trade Information

- (, C, A, ), ', ,, , C, a, i, , e, , I, D, [, ', C, a, s, h, , A, d, v, a, n, c, e, , ', s, h, , n, d, c, A, v, a, n, (, C, ), ', ]

- 10 Ton Per Day

- 2 Days

- Yes

- [, ', S, a, m, p, l, e, , c, o, s, t, g, , s, , s, h, i, p, p, i, n, t, a, x, s, , , b, p, a, i, d, , b, y, , t, h, e, , b, u, y, a, n, d, , e, h, a, s, , t, o, e, , e, r, ', ]

- a, ', A, I, d, [, ', l, l, , n, i, ]

Product Description

Sheet piles are durable, interlocking panels used in construction to create strong, water-resistant barriers. Typically made from steel, concrete, or vinyl, they are driven into the ground to form retaining walls, foundations, or temporary structures. Ideal for projects involving waterfronts, tunnels, and underground construction, sheet piles offer excellent resistance to water pressure and soil movement. Their versatility, ease of installation, and ability to withstand harsh environmental conditions make them an essential solution for effective soil and water management in construction.Versatile Structural Support

SHEET PILES provide essential solutions for construction projects requiring strong earth retention and effective water barriers. Their interlocking steel design ensures stability in marine construction, bridge abutments, and basement work. The wide range of available profiles and thicknesses allows adaptation to diverse engineering requirements. These piles can be customized for specific project dimensions, making them a preferred choice for both temporary and permanent structures.

Engineered for Durability and Performance

Built from high-quality structural steel and available with galvanized or coated finishes, SHEET PILES are engineered to withstand harsh environments. The option of hot rolled or cold formed surfaces further enhances their longevity. They maintain structural integrity even under heavy loads, supporting substantial earth pressures. Advanced sealing solutions are also available for enhanced water tightness, making them suitable for critical infrastructure projects.

FAQ's of SHEET PILES:

Q: How are SHEET PILES installed at construction sites?

A: SHEET PILES can be installed by driving, vibrating, or pressing them into the ground. The appropriate method depends on site conditions, soil type, and the chosen profile. Specialized machinery ensures precise and efficient placement for optimal earth retention and water cutoff.Q: What makes SHEET PILES suitable for marine and waterfront projects?

A: SHEET PILES are crafted from high quality structural steel and can be coated or galvanized for superior corrosion resistance. Their interlocking design and optional sealants provide excellent water tightness, making them ideal for marine construction, waterfront structures, and flood protection works.Q: When should sealants be used with SHEET PILES?

A: Sealants are recommended when water tightness is critical, such as in basement construction, excavation support in wet conditions, or flood protection barriers. Using sealants with interlocking sections significantly reduces water seepage through the joints.Q: Where are SHEET PILES commonly applied?

A: They are commonly used in retaining walls, bridge abutments, waterfront structures, basement construction, and flood protection projects. Their adaptability and strength make them suitable for both temporary and permanent solutions in various sectors of civil engineering.Q: What is the process for customizing SHEET PILES according to project needs?

A: SHEET PILES can be manufactured in specific widths and lengths as required by the project, ranging from 400 mm to 800 mm in width and up to 18 m in length. Engineers assess site conditions and loading requirements to determine the suitable profile, thickness, and corrosion protection measures.Q: What are the benefits of using U-type versus Z-type SHEET PILES?

A: U-type profiles are generally preferred for smaller applications requiring ease of installation, while Z-type profiles offer higher strength and greater moment of inertia, which is beneficial for heavy load bearing and deeper excavations. The selection depends on structural requirements and site constraints.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Shuttering Materials' category

"We are accepting only bulk order quantity."