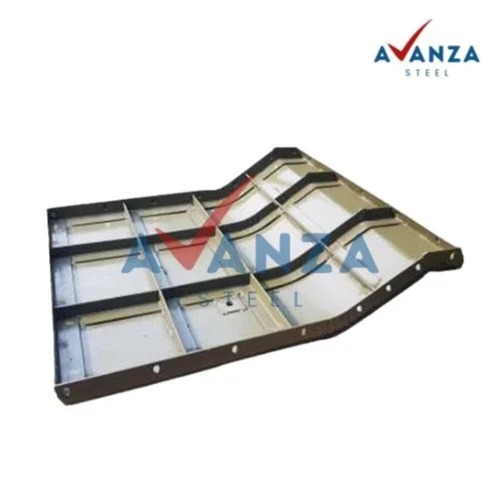

Scaffolding Plates

उत्पाद विवरण:

- रंग Silver, Blue, Black or as customized

- पिन

- गठित करना

- तकनीक

- आस्तीन का आकार Standard as per scaffold requirement

- विशेषताएँ High strength, Reusable, Rust-resistant, Durable

- प्रॉप हेड

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 100

उत्पाद की विशेषताएं

- 100 mm to 150 mm

- Up to 100 kN/m² (varies by design)

- 10 mm to 12 mm

- 3 mm to 8 mm

- Silver, Blue, Black or as customized

- 100 mm to 200 mm

- 100 mm to 150 mm

- 1.5 kg to 4.5 kg

- High strength, Reusable, Rust-resistant, Durable

- Standard and Customized Sizes available

- Standard as per scaffold requirement

व्यापार सूचना

- दिन

उत्पाद वर्णन

Scaffolding Plates are crucial components in the construction of scaffolding systems. This helps prevent the scaffold from sinking into soft ground or uneven surfaces and provide a stable foundation to ensure the safety of workers on the platform. These are used primarily as base plates, stabilizing the scaffolding structure and distributing the load more evenly across the surface. They are typically made from high-strength materials like steel, ensuring long-term durability and the ability to withstand harsh weather conditions and heavy-duty use. Scaffolding Plates provide a firm and stable foundation for the entire scaffolding structure, preventing it from tipping or shifting during use.

Scaffolding base plates are typically 150x150 mm or larger and made of 5-6 mm thick mild steel. These plates distribute the load from vertical standards across a wider area, reducing soil pressure and preventing sinking. Some plates include spigots or holes for pin insertion, improving structural stability. Used in conjunction with sole boards for added ground support.

Uses in the Scaffolding Industry

- Used at the bottom of standards to provide a stable base.

- Reduces point load pressure on ground surfaces.

- Ensures safety by preventing vertical pipe slippage.

- Used on concrete and soft ground with sole boards.

- Helps maintain level and alignment of scaffold structures

Advanced Safety and Durability

Designed to resist corrosion, fire, and tough job site conditions, our scaffolding plates provide optimal safety. Hot dip galvanized or painted surfaces guarantee longevity and rust-resistance, while load-bearing capacities reach up to 100 kN/m2, depending on design. The smooth finish eliminates workplace hazards, helping protect both personnel and structures during construction activities.

Versatile Compatibility and Easy Workability

These plates seamlessly integrate with any standard scaffold system, supporting base, sole, and jack plate requirements. They can be supplied with welded pins, slots, or customized sleeves and are fully customizable in terms of size and finish. The material is easily drilled or welded to suit on-site modifications, making installation fast and flexible for diverse construction needs.

Customizable Packaging and Flexible Sizing Options

We cater to diverse site demands by offering plates in bundles, on pallets, or as per specific orders. Dimensions can be tailored within a range of 100-200 mm length, 100-150 mm width/diameter, and 10-12 mm height, with thickness from 3-8 mm and weights from 1.5-4.5 kg. Standard and custom options ensure fitting accuracy for your project.

FAQ's of Scaffolding Plates:

Q: How are your scaffolding plates compatible with standard scaffold systems?

A: Our scaffolding plates are designed to comply with EN 74 and IS 4014, ensuring seamless compatibility with all standard scaffold systems. They feature standard sleeve sizes, precise dimensions, and universal fitting options, making attachment straightforward across various scaffolding setups.Q: What are the main benefits of using these scaffolding plates in construction?

A: These plates provide high load distribution, corrosion resistance, fire safety, and long-term durability. Their robust design reduces the risk of instability and injury, while their reusable and rust-resistant features make them a cost-effective, sustainable choice for any project.Q: When should I choose a round edge versus a square cut edge plate?

A: Choose round-edged plates when minimizing snagging or injury risk is critical, especially if frequent handling is expected. Square cut edges are preferred for applications requiring close alignment or specific fitting with scaffold components. Both options comply with safety and strength standards.Q: Where are these scaffolding plates primarily used?

A: These plates are primarily applied in construction sites for scaffolding support, construction safety, and effective load distribution. They are also favored by exporters, manufacturers, and suppliers in India for providing secure bases for scaffold towers and support structures.Q: What is the process for installing scaffolding plates on site?

A: Installation involves aligning the plate at the scaffold base, securing it with a welded pin or slot as necessary, and connecting it to the scaffold tube or leg. The plates can be drilled or welded on site for custom modifications, and are available in both fixed and adjustable head configurations.Q: How do you ensure the plates remain rust-free during prolonged use?

A: To prevent rust, each plate undergoes hot dip galvanization or is painted according to ASTM A123/A123M standards. This treatment provides a durable, corrosion-resistant finish that protects the plates throughout repeated site use and adverse weather exposure.Q: What range of sizes and finishes does your product offer for scaffolding plates?

A: We offer standard and custom sizes, with lengths from 100 mm to 200 mm, widths/diameters from 100 mm to 150 mm, and thicknesses between 3 mm and 8 mm. Finishes include smooth, galvanized, painted, or self-finish surfaces, and color options such as silver, blue, black, or as requested.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+